The famous idiom “The best laid plans of mice and men often go awry” couldn’t be more appropriate these days. Supply chain management platforms deal with hypothetical and predictive constraints as part of their solve for uninterrupted results. But unexpected and exceptional events can trigger wildly adverse repercussions even with contingency baked into operational plans.

The Coronavirus – among other upsets, like tariffs – has supply chains scrambling for business network alternatives and “loophole engineering” (similar to what automakers have been doing for years). More than anything else, they’re grappling with the consequences of yesterday’s bad decisions. (It happens). While the focus now is to get things back on track in the short-term, businesses must also start acknowledging the new big picture. It’s time to adopt a platform that is more flexible and therefore resilient to today’s and tomorrow’s upsets.

How did we get here?

Low-cost labor and supporting infrastructure have long made China the world’s go-to option for manufacturing, sourcing, and assembly. Accelerating in the 90’s, China seized the opportunity to build incomparable supplier hubs around the industries.

Today, hedging bets with other-region backstops is no easy task. Even a behemoth like Apple couldn’t easily get away when in 2018 they opted to move some of their Mac production back to the states.

The Coronavirus pandemic has exploited one of the supply chain’s greatest weaknesses: with no alternative supply source as a fall back, companies are vulnerable to risk. The lack of a Plan B is partially owed to the lack of a universal solution. In fact, several of today’s best-selling supply chain software solutions are collections of stitched together legacy apps.

Companies can no longer afford to be short sighted about integration. Uncertainty is here to stay, but you also have the power to be more flexible and agile than ever before.

Black swans are inevitable: How to better future-proof for next time.

Invest now in visibility solutions to protect against more black swan events. It will help you move from a wait-and-see stance to taking action. Doing so can be counter to traditional corporate thinking, but with two major black swan events (trade tariffs and Covid 19 pandemic) in the past year, traditional thinking shouldn’t be what holds you back.

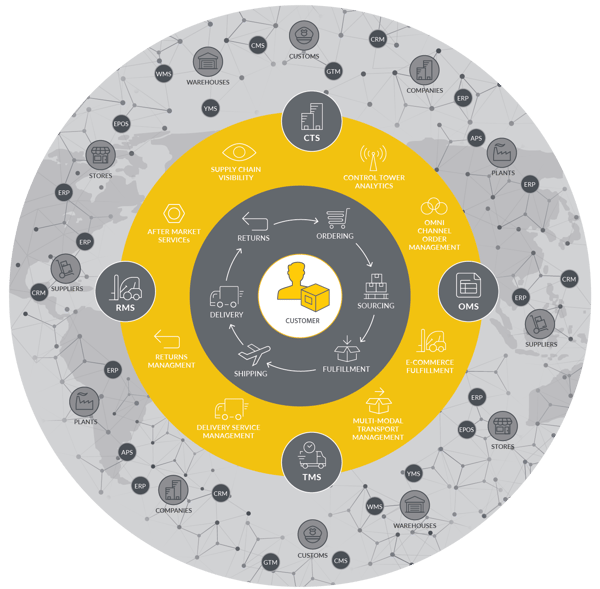

Effective visibility solutions should be highly integrative and offer fast and wide adoption across the full supply chain continuum; that means no proprietary pay walls. It should also extend further upstream and downstream, so businesses can better peer into potential risks and disruptions.

Steer clear of supply chain solution suites that are collections of stitched together apps. They often need considerable customization or third-party point solutions to do what you want. Although they may offer interconnectivity, it is usually through cumbersome middleware connectors and API’s – at additional cost.

The bottom line:

What businesses need now more than ever is a unified Control Tower that openly spans internal and external legacy systems. In addition to upstream, downstream and reverse flow visibility, unified solutions offer incredible levels of flexibility. When disaster strikes, flexible business rules allow you to stay agile by partnering, planning, and executing more dynamically.

Control Towers from unified platforms are also the fastest, easiest, and most cost-effective to implement. Think of each supply chain constituent as a separate node with its own function. An ideal Control Tower for Orchestration platform will offer an application that sits on top of various internal and external legacy systems across these nodes and tie them together in real-time. The app grabs what it needs from all participants, working its magic to identify constraints and suggest solves to keep supply chains moving fast.

There’s no crystal ball, but with a unified platform and network-wide visibility, companies would be set to make proactive decisions. Not only would you have better insight, but with an end-to-end control tower (essentially, a supply chain orchestration platform) you would then also have the flexibility to quickly act on and implement those changes with minimal disruptions.